Belts

Discs

Other abrasives

Tapes & Sealants

Focus products

About us

Mr Daniël van der Poort founded Danpoort in 1932. As time passed, the business expanded in size to become a major industrial supplier of sanding, grinding and polishing materials.

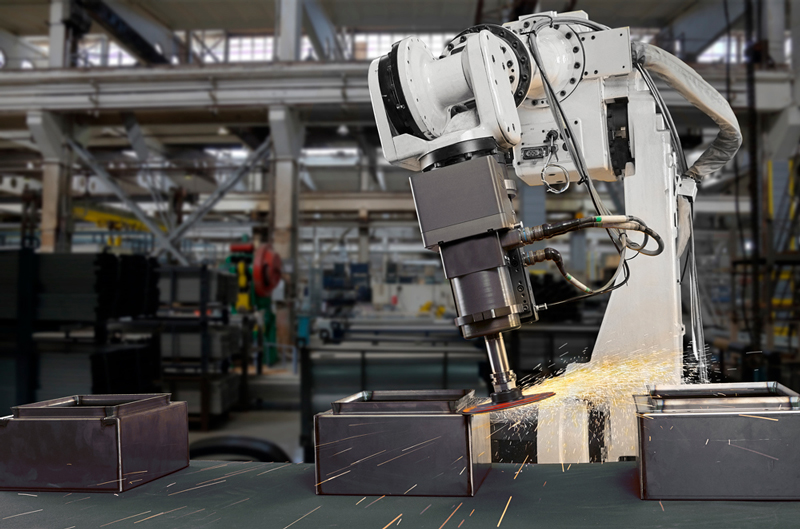

Together with our partner Suhner Abrasive we develop robotic material removal solutions, end-effectors, abrasive materials, process know-how and accessories, easy to implement and easy to adapt thanks to the perfect interaction between them.

Our goal is to increase the usage of robots for productions with high part variabilities thanks to cost effective solutions and a reduced set up time. Food and Pharma industry, metal construction, weld removal, surface sanding are typical segments and applications.

The world is changing and also the manufacturing processes are changing. In many industries we start working with robotic solutions in order to make the processes more efficient. The robot will use a custom end of arm tooling in order to produce a even, clean and finished product.

In the market we see the following robotic applications with the use of abrasive materials:

For all above processes the use of abrasives is very important to get the right result on the final end product. The main advantages of the use of robotics are:

Robotic automation for grinding processes is constantly adapting and evolving at fast rates to meet the desires of the customers. In sanding systems, these advancements make a robotic sanding system even more convincing for the surface finishing needs.

Software and hardware upgrades can significantly improve the grinding, sanding and finishing process on your robot. Therefore it is very important to sett up the robotic automation with an experienced partner which has the know how on the grinding process, the set up on the robot and the use of the right sanding tools.

Danpoort International Abrasives is working closely with Suhner Abrasives. Suhner takes control and let the robots grind in the most efficient way! Contact us for a consult without any obligations. Our main objective is to serve our customers in the best way to start with automation and robotics grinding processes.

Once the robotic process has been set up there is an important step to make in order to get the best result out of the total process.

There are many different products available on the market you can choose for the different applications such as deburring, finishing and polishing. Each brand as 3M Abrasives, VSM abrasives, Norton Abrasives has his own characteristics and influences on the performance of the abrasives.

With an automation and robotics set up the variables as pressure and speed are significantly different in comparison with a manual set up. These two variables need to be taken into consideration with the choose of the needed abrasive material. A ceramic grain from VSM delivers a different contribution to the process then a ceramic Cubitron II grain from 3M. It is important to understand the use and way of working of the different products.

Danpoort International Abrasives offers a very wide range of brands and qualities which enables the consultants of Danpoort to support in finding the most effective setup for your automation and robotics grinding process.